Introduction to Rotameter

3 min readJan 7, 2021

- A Rota meters an expedient that processes the volumetric flow rate of liquid in a padlocked duct. It is a type of meter known as variable area meters, which calculate the rate of liquid flow by changing in the cross-sectional area when the liquid passes through that area, producing a quantifiable consequence.

- A rotameter comprises of a tapering tube, characteristically prepared of glass with a ‘float’ (a molded weight, prepared either of anodized aluminum or an earthenware), intimate that is strapped up by the drag force of the movement and dragged down by gravity.

- An advanced volumetric flow rate through a given area upsurges flow swiftness and drag force, so the float will be strapped up. Though, as the inside of the rotameter is funnel formed (widens), the area about the float through which the middle flows upsurges, the flow speed and drag force drop till there is mechanical equilibrium with the float’s weight.

- Floats are prepared in numerous altered forms, with spheres and ellipsoids being the most communal. The float can be slantwise fluted and partly painted so that it alternates axially as the liquid passes. This displays if the float is wedged subsequently it will only swap if it is free. Interpretations are frequently taken at the upper of the broadest part of the float, the midpoint for an ellipsoid, or the topmost for a tube. Some builders use a changed standard.

- The “float” must not float the fluid: it has to have a greater density than the fluid, else it will float to the topmost even if there is no flow.

- The automatic nature of the gauging principle delivers a flow measurement expedient that does not need any electrical power. If the tube is made of metal, the float location is transported to an exterior pointer via a magnetic connection. This competence has significantly prolonged the variety of submissions for the adjustable area flowmeter since the measurement can be detected tenuously from the procedure or used for automatic control.

Construction of Rotameter

- There are two main parts it has first one is a Graduated tapering metering cut-glass tube and the second is Float. Let’s discuss them one by one.

Tapered tube:

- Safety protected glass tube is in universal use for gaging both fluids and gases. Metal tubes are used wherever dense fluids are used or temperature or pressure condition is pretty high. Plastic tubes are also used in certain rotameter enterprises due to their lesser price and extraordinary influence power.

Float:

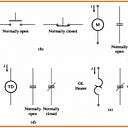

- Floats can be created of metals of numerous thicknesses from lead to aluminum or from glass or plastic. Stainless-steel floats are communal ones. Float figures and sizes are also various for altered submissions. For minor movements floats are sphere-shaped. In the given diagram, you can see different types of floats.

https://www.theengineeringknowledge.com/introduction-to-rotameter/

Let’s see a diagram of floats.

Now we discuss how it works, we will also study its working principle.