Ordering Instructions at JLCPCB — The Engineering Knowledge

Hello, readers welcome to the new post. In this post, we will discuss Ordering Instructions at JLCPCB. JLCPCB Established in 2006, JLCPCB is at the forefront of the PCB industry. With more than 15 years of continuous innovation and improvement based on customer needs, they have grown rapidly to become the world’s leading PCB manufacturer, providing rapid production of highly reliable and cost-effective PCBs and creating the best customer experience in the industry. Ensuring quality and continuous improvement are the two main principles of our company. their advanced PCB technology enables them to provide high-precision boards suitable for industrial, military, aerospace, and medical applications.

They continuously invest in top-quality base materials and advanced equipment for fully automated production lines, enabling them to offer our customers high throughput with consistently high quality.

In this post, we will clarify woe points that users face during placing orders at JLCPCB for their products and different services. There are some operations performed by the JLCPCB after getting the order to avoid any issues here are some instructions discussed that will helpful for you before placing any order on JLCPCB. So let’s get started

Ordering Instructions at JLCPCB

Instructions for PCB orders

Solder-resistance bridges

Proper English descriptions and other attachments in the zip file

PCB file and GERBER file in the zip file at the same time

Plated edges/ slots Dimensions

Problems related to software incompatible

Markings on base materials

Designs about slots/CUT OUT/ millings/ v-cut

Gerberview Error

Silkscreen/ texts

- For a clear silkscreen on board, the width of text and spaces between letters are required to be not less than 0.15 mm with a height of about one mm. The acceptable ratio for width to height is 1:6. If the outline font is designed and a solid portion is filled with lines then the filling line needed to be not less than 0.155mm and the hollow part to be more than 0.2mm

- Normally they will not check and modify the silkscreen in the Gerber file but texts can be widened to 0.15mm if it is not enough. And they do not get the comparing related unclear texts caused by non-standard design. Ensure that the silkscreen is according to JLCPCB capability before order placements

- When silkscreen overlaps to openings they will follow the principle of opening first. In simple words, they will not consider silkscreen and open the board only. Under circumstances, if your need to keep the silkscreen on open make sure to add the note in remark column so they can inform their engineers to pay attention to it to fulfill your requirements

Silkscreen on Aluminum PCBs:

- They currently support white and black screen printing colors for aluminum plates. The white screen print will be applied to the green and black solder mask ink, while the black screen print will be applied to the white solder mask ink.

- Please note that screen printing is not recommended on a bare aluminum surface due to its low level of adhesion and will therefore easily peel off the surface.

- The white screen print was not clearly visible on the off-white bare aluminum surface. Please specify your requirement in the remark column if screen printing on bare aluminum is actually required.

4 Layer PCB

About repeat order

- Normally order reputation is directly generated on the basis of the production file for your previous order and they will not make any variation to the production file anymore. Therefore make sure you do not leave any notes related to order changes when you place an order. The repeat order will not longer be manually checked by their engineers

- Note: The engineering fee will still charge by the system since our engineers need to re-penalise the boards manually.

About the items in the board outline

file generated from Easyeda

About JLCPCB panel

Remark field

About the board that is larger than 200mm*250mm

Design about the thickness

About the board within or equal to 50mm*50mm of board outline /slots/CUT OUT/ millings Solder mask layer

order cancellation

About orders beyond JLCPCB capabilities

Other instructions:

stencil production file

About Removing Order Number:

Stencil thickness

English descriptions and other attachments in the zip file

Instructions for Stencil ordering at JLCPCB

Tooling holes

Solder beading treatment

About the spacing for different designs in your stencil file

Direction of stencil

- Solder balls, a defect that can result in short circuits, are generally related to excessive solder paste deposits that, due to the lack of “body”, are compressed under the discrete component and then become a solder ball. The most common place to see solder balls is on the side of chip components such as resistors and capacitors.

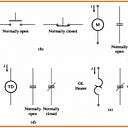

- On the JLCPCB, the template hole for components (except the diode) greater than or equal to 0805 will be slightly reduced from the size of the pad as shown below to avoid solder balls.

Note: If you do not wish to use this solder bead modification for your template, please indicate so when placing your order.

apertures for thru-hole components in stencil

Other instruction Complaints about the reorder order

Originally published at https://www.theengineeringknowledge.com on February 19, 2023.